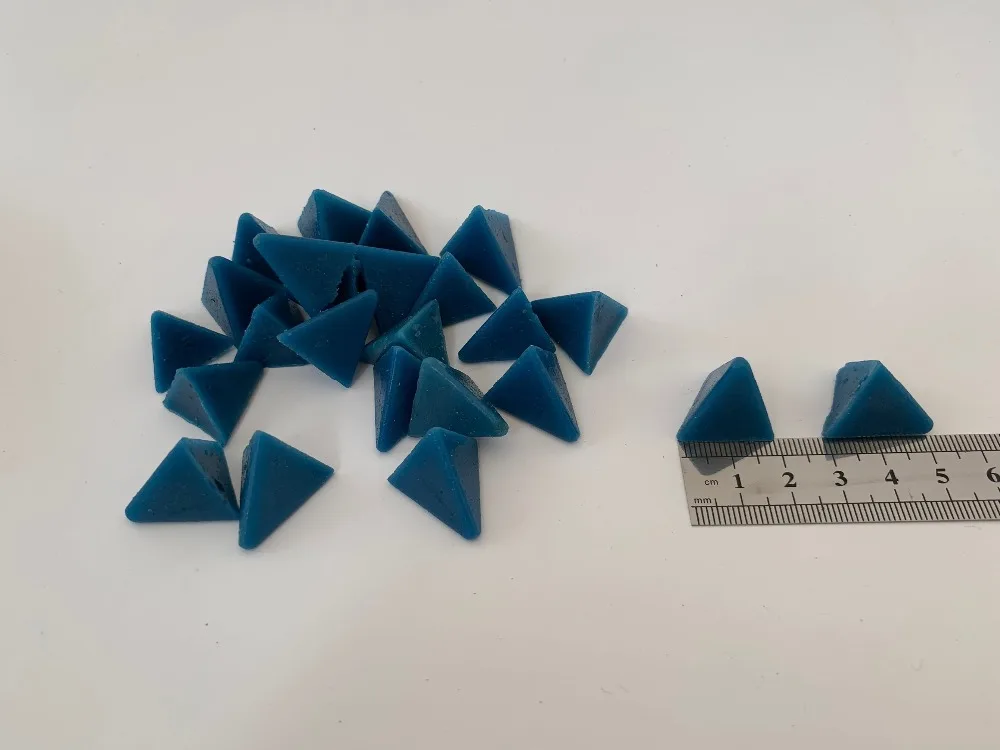

450g of Jewelry Polishing Media Rock Tumbler Lapidary Filler porcelain abrasive stone stainless steel jewelry burnishing ballcone

450GR

JEWELRY POLISHING PORCELAIN CERAMIC MEDIA ROCK TUMBLER LAPIDARY FILLER POLISH FOR JADE/AMBER/GOLD/SILVER/IRON/SIVE...

3*6mm

20x20mm

Dia 3mm

1.3*3mm porcelain abrasive stone

3.5*5mm Stainless Steel

Code of application:

Mainly used for "rough grinding". Used to remove burrs, flash, scale, rust and streaks in metal. To lay a solid foundation for fine grinding.

Tips: Whether it is rough grinding or fine grinding, burring or polishing, if you want to achieve the best results, it must be used together with the polishing liquid and brightener, because in the vibration grinding process, the surface of the parts is bright, can you When it meets the requirements, the polishing liquid and brightener play a decisive role!

Operation and use

The type, shape, size and loading of the grindstone:

The machined parts and the grinding stone that meets the purpose of grinding, material properties, size and shape are placed in the tank to reach more than 95% of the total volume (mixture of machined parts and grinding stone). When using new abrasives, it is best to first grind the abrasive itself for half an hour to remove dirt and sharp edges from the abrasive surface.

Mixing ratio of grinding stone and machined parts:

It should be determined according to the size of the machined parts, the nature of the opening material, and the condition of the grinding stone. Generally, the ratio of the machined parts to the grinding stone is about 1:1 - 1:3. For rough polishing and medium polishing, the ratio is smaller. When the finish is fine, the ratio is larger.

The amount of water added:

The water generally takes 3~5% of the total volume of the drum container, 3% is coarse grinding, and 5% is polishing. If too much is added, it will cause resonance phenomenon and affect the grinding effect, so it is necessary to control the amount of water added.

The amount of abrasive added and the durability:

According to the purpose of grinding and the nature of the material, the appropriate abrasive should be selected. The addition amount is divided into two types, the heavy cutting is about 360g, the polishing process is about 600g, the endurance time is one hour, and the grinding time is more than one hour. The abrasive is replaced midway. In the process of replacing the abrasive and water, the previous abrasive and water should be drained, the abrasive and parts should be cleaned, and then the abrasive and water should be re-added.

Determination of grinding time:

The choice of grinding time should be changed according to the condition of the machined parts. Usually, the best time is found on the basis of the process test, so as to determine the grinding schedule of a tomb.

Cleaning of machined parts:

Before processing the parts, the parts must be degreased and decontaminated. If not done, the service life of the PU glue and the grinding effect will be reduced.

Separation of parts from abrasives:

After processing, the workpiece can be cleaned directly in the spiral container while the drain valve is opened. After the cleaning, the appropriate size of the separation screen can be selected, and then the separation joint plate is placed to automatically separate the parts and the abrasive, and the parts should be cleaned, dried and rust-proofed.